How to Make a Knife Step By Step

A knife is a fundamental tool, one of the first ever crafted. It’s an essential tool for almost everybody. You can use a knife in the kitchen when preparing food or for camping and hunting. In worst cases, it becomes self-defense tools. So, making your own knife isn’t “mission impossible.”

How to Make a Knife Handle

When making any knife, no matter of type or size, it’s crucial to make one with a comfy handle which won’t flip or spin around in hand. The blades are all the same, but it’s the design of handles that makes a difference.

How to Cut Stainless Steel

According to the SSINA, stainless steel isn’t a single alloy, but rather the name applies to a group of iron bases alloys containing at least 10.5% chromium. Other added elements and the chromium increase corrosion resistance, improve heat resistance, enhance mechanical properties, and improve fabricating characteristics.

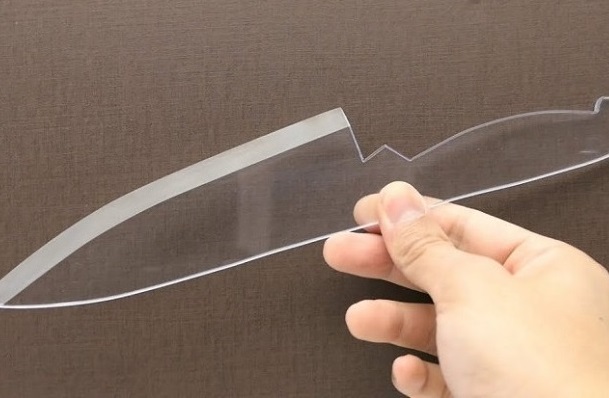

How to Make Sheath

The sheath can make or break how the knife is carried and also the look of it. You don’t want to just cut out of a piece the leather, fold it over and stitch it. You want to make a knife sheath template functional and esthetical at the same way.

How to Cut Metal - 7 Simple Ways

There are 116 metal elements, and plenty of variations and each one requires different cutting methods. The most efficient tools of how to cut metal are the cut-off wheel and grinding disc. We will show you 7 simple ways in a few steps how to cut metal. Important: before start, always take some protection measure.

How to Become Welder in 2021?

Welding School, Training and Certification – Want to become a professional welder! It takes a lot more than just watching online welding videos or playing around in a workshop. In order to accomplish that goal, you’ll need to attend official training and get credible certification.

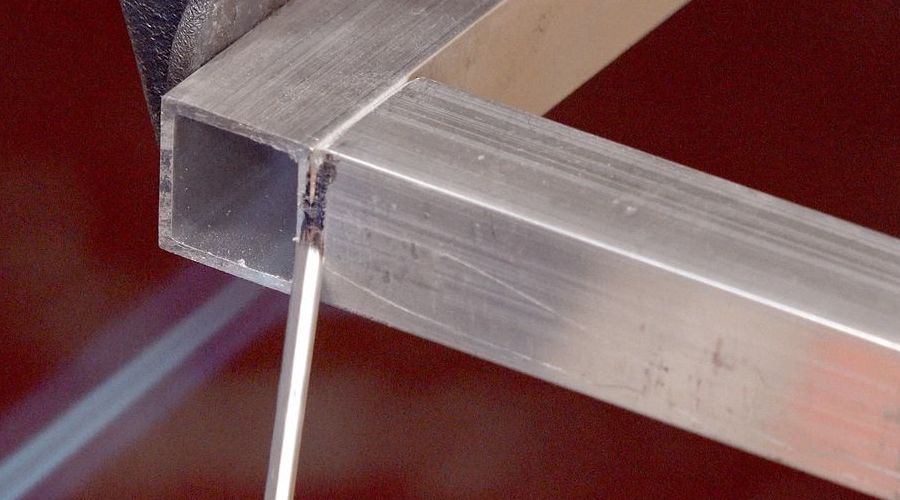

How to: Brazing Aluminum

Brazing aluminum is more challenging than brazing other metals since the melting points of the base metal, and the filler is close. At the same time, brazing aluminum produces an oxide layer on the surface.