How to Remove Solder Quickly and Efficiently: Advanced Tools and Methods for DIY Projects

You need the adequate solder removing tool whenever you’re looking to salvage or replace specific electronic components attached to the circuit board. You can do it using different DIY methods and tools, such as a desoldering pump.

Methods and tools you’ll use depend on your budget and expertise level. Apart from basic, cost-effective kits convenient for beginners, there are advanced and professional solder removal tools designed for specialized tasks. It is worth investing in them whenever your projects require particular speed and precision.

This article will walk you through the best methods for removing solder, including the most suitable set of tools that will help you complete the task more quickly and efficiently.

Removing Solder At-a-Glance

Before we move on to the best unsoldering tools and methods, let’s see some general rules of desoldering a circuit board.

There are many ways to remove solder from your circuit board. The method you choose will depend on the task complexity. While smaller DIY projects may require a simple desoldering pump and braid, more advanced tasks call for more advanced techniques and machine-powered tools. Still, your final decision will depend mostly on your personal preference.

Choosing a Solder Removal Technique

The first step is choosing the proper removal technique. Neither one is perfect per se, but you will select a particular one based on what you are desoldering, where it is, and how big it is.

Let’s see the most common unsoldering methods:

- Grinding and scraping are the two most basic desoldering methods. They work with most projects, requiring only a knife, scraper, or pick. These techniques are quite controlled and methodical, and the final result may depend on your technician skills. However, they may be time-consuming and tiring.

- Machining and milling take less time than scraping, but you need a higher level of skills and expertise to perform them. The milling machine drill may damage the circuit board if used incorrectly.

- Chemical stripping uses a liquid chemical solvent that should be applied with a brush or swab. This technique is suitable for removing solder from copper plates. It is recommended to use masking tape or protective material to protect the circuit.

- Microblasting is convenient for desoldering large surface areas. This technique includes a small bench-top system that pushes abrasive materials at the target area through a pencil-shaped piece.

How to Desolder with Soldering Iron?

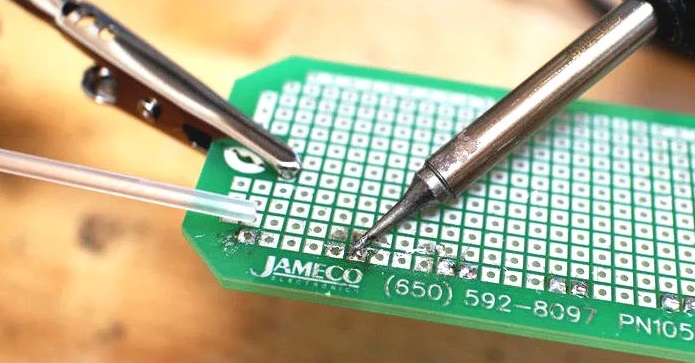

If you already have a soldering iron, you may want to use it for your desoldering project. You can use a soldering iron to heat the solder and fiddle with it until the components are out.

Here is how to use a soldering iron to desolder circuit board:

- Heat solder with the iron

- Slide the iron up the pins to keep the most of the solder away from the joint

- Use pliers to gently pull at the components to remove their pins from the pinholes while they are still hot.

Techniques involving a soldering iron are pretty convenient for DIY tasks since you need only one tool – a soldering iron. Besides, all the components can be used again. A potential downside is that the board can be damaged if you leave the soldering iron on it for too long.

MORE TIPS FOR MAKERS:

- 10 Must-Have Soldering Tools for Hobbyists & Professionals

- Best Soldering Iron in 2022: Top 13 Choices for Beginners, Hobbyists, and Professionals

- A Complete Guide to Choosing a Grinding Wheel in 2022

- A Fundamental Guide to Soldering

- Super-Simple Guide to Welding Joints

- Welding – The Art of Metal Fusing from Bronze to Information Age

- Brazing 101 – All You Need to Know

- 7 Simple Ways to Cut Metal

- How To Polish Stainless Steel With 7 Proven Techniques

- Hobo Nickel Tools In-Detail

How to Desolder with Desoldering Braid?

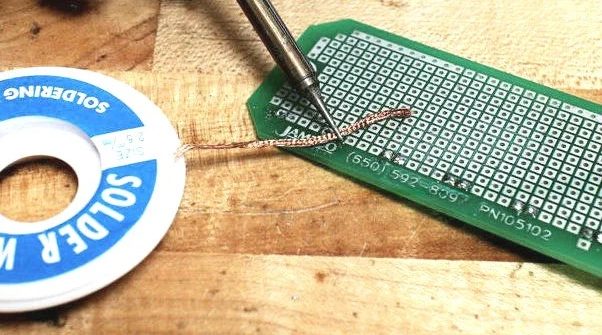

Desoldering braid or desoldering wick is an excellent method that can help you soak up unwanted solder. It contains strands of wire that are braided together. Some desoldering braid also has flux, which allows you to remove the part much easier and cleaner. If your soldering braid doesn’t come with flux, you can dip the braid’s section into the flux later.

Here is how to use desoldering wick:

- Unwind a few inches of braid

- Add a bit of flux to the braid section (if your wick doesn’t contain any)

- Place the braid over a joint that needs rework

- Place a hot soldering iron against the braid and the wanted pin

- Wait a couple of seconds for solder to flow off the pin onto the braid

- Remove the braid. But touch the spool only because the braid will be quite hot at this point

- Remove the component

- Repeat steps from 1 to 5 to remove the solder left.

Methods involving desoldering wick are easy and cheap. Since desoldering braid comes in various sizes, it is convenient for different projects and the magnitude of the solder you want to eliminate. It is excellent for removing solder from flat surfaces.

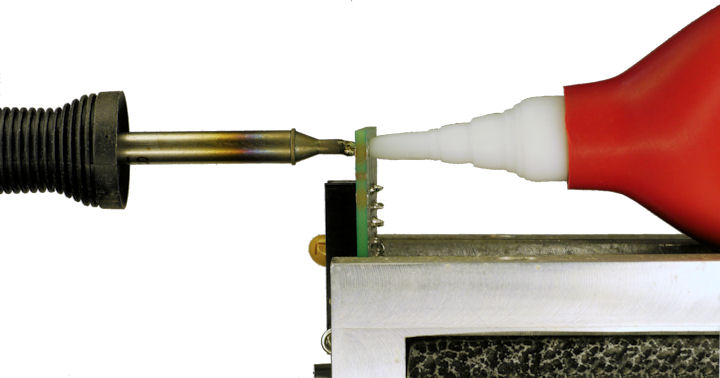

How to Use a Desoldering Pump?

A desoldering pump is the most commonly used solder removal tool. It is a small, high-pressure vacuum you can use to suck the solder up and out of the way after heating it.

Here is how to use desoldering pump:

- Use a soldering iron to heat the solder you want to remove

- Press down on the plunger or the bulb

- When the solder is molten, place the pump’s tip against the solder you wish to remove

- Release the plunger/bulb

- Remove free component

- Repeat the steps from 1 to 4 o remove any solder that has left

- Get rid of the solder inside the pump by pressing down and releasing the plunger.

Desoldering pumps are available in various styles, from handheld pumps to electronic heated guns you can use without the iron. In essence, they are excellent for reworking small parts and getting solder out of pinholes. However, it may be hard to get into tight spaces due to the pump’s size.

How to Desolder with a Heat Gun?

You can use a heat gun to remove solder without a soldering iron. It heats the solder enough so that you can remove the components quickly and efficiently. If you have a heating gun, here is how you can use it to remove solder:

- Turn on the heat gun

- Use pliers to hold the circuit board

- Have a pair of needle-nose pliers to pull the components out of the board.

A heat gun is an outstanding way of removing solder without using a soldering iron. Still, you must be careful when using it because the board can become very hot, resulting in damage or finger burns.

How to Desolder with Compressed Air?

If you don’t have any of the tools mentioned earlier, you can remove solder using other equally efficient techniques. Compressed air is one of those methods. All you need to do is to blast molten solder away.

Don’t forget to wear safety glasses during the process.

Here is how to use compressed air to remove solder without a particular desoldering tool:

- Heat the solder with a soldering iron

- When the solder is molten, get the nose of the compressed air can close to the joint

- Blast it with air.

Anyone who tried compressed air for solder removal claims that it is quite funny and quick but messy at the same time. You must be careful enough to prevent the solder from getting all over your workspace.

How to Remove Old Solder?

Some connections may be difficult to desolder. Such projects may be tiring and time-consuming, especially since you’ll have to repeat the desoldering processes involving soldering iron and pump multiple times to ensure all the necessary components are removed.

If you are dealing with complicated connections or old solder, follow the next steps to remove solder successfully:

- Apply flux to allow the melted solder flow

- Melt new solder to mix in with the old and hardened solder

- If you have through-hole connections, use the tip of your soldering iron to slowly wiggle the terminal from side to side to break the connection to the sides of the hole.

How to Remove Solder from PCB Holes?

Removing solder from surface-mounted components differs from through-hole soldering, which requires a bit different approach. Let’s see the best methods for removing solder from circuit board holes:

Use Desoldering Bulb

Desoldering pumps can significantly help you remove the solder from circuit board holes. After you preheat the PCB hole, suck the solder off the board by squeezing and releasing the bulb from behind the hole.

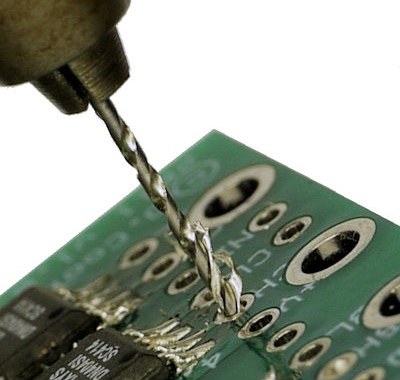

Use a Drill

If you cannot use a bulb or don’t have one, you may opt for a drill. Still, make sure you use a small carbon, cobalt, or high-speed steel bit since most circuit board holes are about 0.029 inches in diameter. Oversized bits may remove the tracing within the hole, damaging the board.