Knife Blade Design: Dead-Simple Guide to Find Perfect Blade Shape

The designing of knives is art, yes there’s a craft aspect to this which is making things more effective, but people respond emotionally, aesthetically, and artistically to even the simplest designed knife. Knives are around us since the begging of the world. They can be used to prepare food, for combat, or work. There are many types of knives with different designs, shapes, and purposes. A knife is divided into two main parts, the blade, and the handle. But each of the two elements can also be subdivided into its own sections.

In this guide, we'll focus more on a blade, blade designs, blade shapes, and blade characteristics.

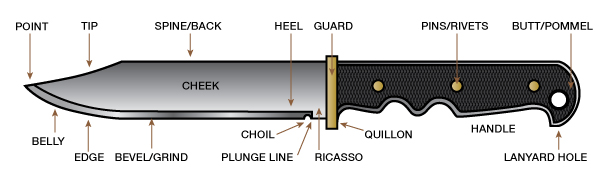

Knife Blade

A blade is a part of a knife with an edge designed to slice, chop, scrape or puncture. Blades are crafted from material that is harder than those they’re to be used on. They're one of humanity's oldest tools, and continue to be used for food preparation, hunting, camping, and other purposes. These are central parts of blades:- Bolster – The bolster is the part that connects the blade of the knife to handle. The bolster makes a balance for the knife and also protects the hand from getting in the way of the knife edge,

- Heel – The heel is the rear portion of the blade,

- Spine – It is the top of the blade, opposite the blade edge,

- Edge – It is the cutting part of the blade. Edge expends from the point to the heel of the blade,

- Tip – The tip is the front part of the knife and includes the knifepoint. It is used for detailed or delicate cutting,

- Point – The point is the portion of the blade where the spine and edge come together. The point is typically used for piercing.

Knife Blade Designs

Numerous knife blade designs are used for many purposes. So, it should be noted that as a rule, each blade shape is specifically designed to enhance a knife ability to perform a specific task. Below is the list of the most popular knife blade designs.Bowie Knife Designs

This sheath knife is also called Arkansas toothpick, was popularized by 19th-century pioneer Jim Bowie, and it's made from durable, high-quality steel and comes with versatile hunting knife designs. It is a convenient blade and can effectively use for hunting, skinning, deboning, butchering, and caping. The Bowie blade is an excellent solution for survivalists since it is so robust.Clip Point

This is one of the most common knife types. The clip-point blade is formed when you use a standard blade and clip the back which results in a thinner tip. This thin tip can be applied to cut in hard to reach places and provides more control. A Bowie blade is a typical example of a knife with a clip-point blade. Typically, the clip is concave, but it can be straight too.

Drop Point

The drop-point blade takes a convex bend on the knife back near the tip. The convex bend is less suited to piercing but offers more stability than a clip point. You'll find many modern pocket knives today with drop point blades, and it's useful in most applications.

Spear Point

The spear-point blade is symmetrical and bend the same on either spine side which streams to the blade center. It can be sharp on both edges or only on a single edge which is typical for penknives. Usually, you’ll find spear-point blades on daggers and other knives crafted for throwing or thrusting.

Trailing Point

The trailing-point blade has a characteristic back edge that curves up which allows for improved slicing ability. This blade provides a sizable curved cutting area "belly" particularly useful for skinning or slicing. Trailing point blade is also favorite on filet knives with great knife tattoo designs.

Normal Blade

This type of blade is easy for handling. A normal blade has a dull, flat back and a curved edge. Since the end is not sharp, it allows you to use hand or fingers to apply added pressure to boost the cutting. Also, it's great for chopping or slicing. Still, the dull back increases the weight of the blade, so these knives are heavier.

Needle Point

It is a symmetrical blade but tapers much more sharply, and therefore it isn’t particularly strong. Still, needlepoint can be used efficiently to penetrate or pierce. You’ll see this blade mostly on daggers designed for close range combat like the spear-point.

Spey Point

The spey-point get the name from being used to neutering livestock. It includes a straight edge that bends upward at the point with a small clip on the heel. This kind of blade does not really provide a point and therefore not suitable for penetrating but very adequate for skinning animals.

Tanto Blade

The tanto knife has a chisel edge inspired by Japanese swords which offers excellent strength. The Tanto gets its name by the tip of a broken samurai sword which was very effective at stabbing armor. These knives have no “belly” so will not be able to slice but instead, make up for it with high tip strength that can penetrate anything. You'll find many varieties of tanto blades, and they’re becoming popular in certain tactical knives.

Sheepsfoot Blade

This blade is almost the opposite of the regular blade by providing a sharp straight edge, and a dull back which is much straighter then curves at the end. These knives can be tightly controlled by fingers being placed on the dull back and were used initially for trimming the hooves of sheep. Ideal for chopping but without a sharp point which can be a plus in many cases as it prevents accidental stabbing.

Wharncliffe

Wharncliffe is a thicker blade but very similar to the sheepsfoot, but the back starts to curve towards the tip much earlier and at a slighter angle. Wharncliffe blades were typically used by sailors as the shape of the tip was made to prevent the sailor stabbing himself as a result of being jolted by the waves.

Pen Blade

The pen blade is typically found on smaller folding pocket knives and similar in shape to the spear point blade but with a more gradual curve. One side is dull, and the other sharper just like Swiss Army and similar pen-knives.

Hawkbill

This blade includes a curved back as well as a curved cutting edge. Hawkbill comes with unique camp knife designs. With a downward point, it is ideal for actions like whittling, scraping and camping.

Knife Blade Shapes

Knife blades are shaped differently for a reason. Below, you’ll find reliable information on how to recognize the most commonly knife blade shapes, and what they are used for.- A can opener is used for opening the diverse types of cans,

- Clip blade is the primary blade especially in large folding hunters,

- A coping blade was used for working close to outlines like a second or third blade,

- Manicure blade is often seen as one of the small blades in a whittler,

- Pen blade was made in the days of quill pens. They used for sharpening the quills points. This blade was ideal for splitting and sharpening the point,

- Pruning blade is designed for removing limns or small branches,

- Punch is a typical blade in cattleman knives used for putting holes in plastic or leather,

- Razor blade is an old blade shape that was used for shaving,

- Screwdriver blade was used in utility knives,

- Spear blade is used typically on throwing a knife.