100 % Covered Welding Tools List

In case, you’re curious about welding as a hobby or as a career or thinking how to get welded without “line of credit” then “explore” this welding tools guide.

You might overhear that “jumping” into welding is breaking the bank situation, but the reality is that there are only several basic welding tools that you’ll use frequently.

So, it’ll be helpful to know the stuff you need before ending up acquiring things a random or what folks just suggest you buy.

Our final destination with this article is to demonstrate the top 14 pivotal welding tools and equipment that should be in any shop.

Tool #1 Welding Machines

A welding machine or welder is an appliance that delivers an electric current to perform welding. They’re usually classified as CC (constant current) or CV (constant voltage). A CC machine varies its output voltage to maintain a steady current while a CV machine will fluctuate its output current to maintain a set voltage.

The AC/DC settings, duty cycle, and voltage power are some of the most critical elements to consider when picking a welder machine. The appliance will need both the power and sufficient operating time (the duty cycle) in order to complete every project.

Best brands in this industry are Lincoln, Miller, and Hobart. Some appliances are quite aordable now, and you can nd a proper welding machine for $300 to $600.

Deciding between TIG, MIG, and stick welders is a skill, convenience, portability, managing costs, and the purpose of the task.

TIG welding makes high quality, clean welds, but it is tricky to master. While, MIG welding is merely to use, but it’s expensive and not portable like the simple stick welding operation.

MIG welders dier from ARC welders fundamentally since they use a fed wire instead of rods. The wire is supplied from the feeder or roller by a torch and then protruded from a tip. As most wires are just metal, the weld must still be shielded, since an inert gas is also fed throughout the torch to protect the weld from moisture and oxygen.

The key factor for MIG machines widespread use is the advances of being capable of welding continually in longer period liken to rods or TIG welding.

The welder can weld until the roll still is being fed and the operating time holds out. This makes it wellliked in the fabrication business where longer welds are required like water tanks or sealing pipes.

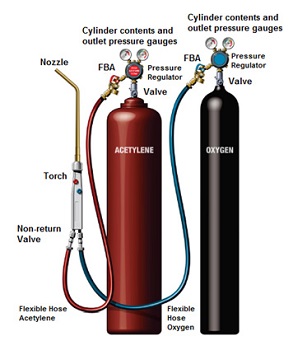

Tool #2 Oxy-Acetylene Setup

Oxyacetylene has various and vital uses such as cutting, forming, hardening, bending, tempering, preheating, post-heating, brazing, braze welding, preheating, and post-heating. It provides excellent control of heat input and puddle viscosity as well as good control of bead size and shape.

Due to the precise control, the welder has over oxyacetylene heat input and its high-temp flame together with its affordable equipment cost, portability, and skillfulness, oxyacetylene torches remain as vital welding equipment. No welding shop or even industrial shop is complete without this equipment.

Need to cut ideal circles? You can quickly achieve this with an oxy-acetylene setup. Just ensure to follow proper safety precautions since it’s the most dangerous piece of welder equipment in the garage. You can use a small oxyacetylene setup for cutting steel, but it won’t be able to cut stainless steel or aluminum.

It is a fundamental tool for welding since you can perform almost anything with this equipment. You can weld, cut stuff with this and then even bend application with this.

Also, Oxyacetylene heats metal quickly, and you can buy a decent one for about $200. Only sun, nuclear explosions, and welding arc plasma, produce higher temperatures than a 5600°F oxyacetylene flame.

Tool #3 Welding Torches

The welding torch is one of the fundamental pieces of welding equipment. Its primary function is to regulate and maintain how the gases travel during the welding process.

This device is made from a handle, mixing chamber, gas, and oxygen valves. The oxygen and gas ow through the handle mixes at the tip and ignites.

Also, the torch transfers the welding current to the electrode. For consumable electrode process, this means delivering the current to the electrode while the electrode moves through the torch.

It is applied in an automatic welding system to transfer the welding electrode into the arc, to provide shielding of the arc area, and to conduct welding power to the electrode.

There are various kinds of welding torches according to the welding process, electrode size or welding current.

Torches can also be classied according to the way of cooling. So, the torches may be air-cooled with ambient air or water-cooled with circulating cooling water. It can be utilized for a consumable electrode welding process such as GMAW or FCAW.

This tool can be described as a straight torch or with a bend in its barrel. A torch with a bend is mostly utilized for robotic arc welding applications to make access for the weld.

It’s an aordable piece of welding equipment, and with $100 torch investment, you’ll complete your welding shop

Tool #4 Electrodes

An electrode is a tip that is inserted on the end of the welding tool and through which the electric current is transferred from the welder to the material. For dierent applications, you’ll need a specic type of electrode.

There are some electrodes that match each of the 4 main welding processes. SMAW (shielded metal arc welding) uses a consumable electrode that is melted to make the weld joint. The E6010 model is one of the most used electrodes, but the E6011, E6013, and E7018 are popular also as an excellent solution for welding.

Metal inert gas welding utilizes a consumable electrode wire that is fed by the welding torch. Most undertakings apply wire in the following scope of thickness: .023; .030; .035; and .045; Still a thicker wire may be required for larger projects.

TIG (tungsten inert gas welding) welders’ employee non-consumable electrodes that come in 5 main types. Ceriated and lanthanated electrodes are both great options for most TIG welding applications. “Skip” thoriated electrodes because they emit radiation when used in welding projects.

Also, electrodes utilized for SWAW and MIG welding dier from those applied for TIG welding. The electrodes for TIG welding are fabricated of non-consumable tungsten. It means that unlike with SWAW and MIG welding, TIG electrodes don’t require regular replacement.

It is a coated metal wire made of materials similar to the metal being welded. For newbies, there are consumable and non-consumable electrodes.

Consumable electrodes have a low melting point.

These types of welding electrodes are used mostly in Metal Inert Gas (MIG) welding. For making consumable electrodes, materials like nickel steel and mild steel are used. These kinds of welding electrodes are not consumed in the whole welding process since they don’t melt during welding.

The non-consumable electrodes have a high melting point and aren’t capable of lling the gap in the workpiece. They are made from materials such as pure tungsten, graphite or carbon coated with copper.

Electrodes are budget friendly welding accessory, and one set of them costs about $20.

Tool #5 Angle Grinders

Angle grinders have many uses, and it’s useful to have at least two, one with a cutting wheel that has a thin cut, and one with sanding or grinding wheel to remove scale, prep surfaces, chamfer corners, and smooth welds.

You can put a grinding disk on to smooth out applications, put a cut off wheel on to cut metal, put a wire brush on to remove paint or put a flap disk on for precise grinding.

Before you start welding, always use the angle grinder to remove paint, dirt, or rust from the application.

They are crucial for preparing metal before welding, especially for TIG and MIG welding. The angle grinders are the mobile tools which include the arbor at 90° concerning the tool. Depending on their size, grinders range from 500 to 2500 watts.

Every welding task is different, so selecting a grinder with more power and durability can make major progress during welding projects.

Even though the investment in quality tools and angle grinders is the best quality solution, you can also buy one for only $15 from some lower quality brands.

Welding Abrasives

Best way to minimize costs and maximize outputs when you’re welding metal is to choose the right abrasive and use it adequately.

Your choice depends on balancing results you want with the cost you’re able or willing to pay. In case the initial price is your primary concern, pick proper abrasives, but be aware that lower buying cost up front may not end up being economical in the long term.

If you’re working on high-productivity applications and have to keep in mind initial abrasive prices, it’s time for high-quality abrasives. Take into account the best abrasives when maximum productivity and lowest total cost are crucial to your operation.

Tool #6 Chop Saw

A chop saw is commonly used for specific cuts that an angle grinder can’t perform or at least do elegantly. It’s a portable device and adequate for cutting metal that is roughly 3/4″ thick or less. Thicker metals will be challenging to cut, resulting in uneven metal pieces and time lost for the work. Chop saws are specially designed tools that make construction projects easier and more suitable.

The crucial rule for utilizing a chop saw is to switch to a thin blade when cutting thicker metal. Unlike oxy-fuel cutting, a chop saw will produce bits of metal all over, making a mess during the cutting.

This device assists in cutting metals without any damage to the blade. Chop saw apply a high-speed abrasive to cut smoothly through and prevent any contaminations. Welders need to work with the right metal cutting chop saw to fasten their work and improve the quality of the weld.

When choosing the right chop saw for welding use, it’s vital to ensure that it meets several demands. Therefore, always consider the size, blade speed, and brand.

You can pick a carbide blade chop saw, an abrasive chop saw, or even a bar cutter chop saw for only $80. It should also be designed for the material you need to cut. Chop saws are specialized tools that make construction projects simpler and more convenient.

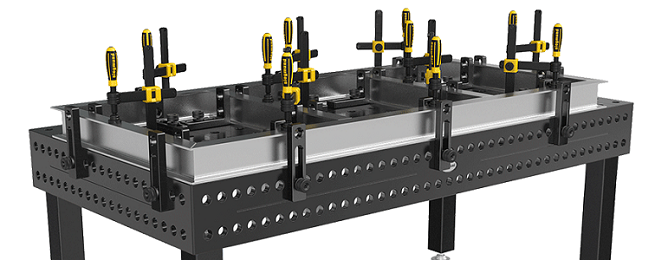

Tool #7 Welding Tables

It is a platform that is at waist level, and it works like a workbench. The workbench is using while working in metal fabrication with welding. A welding table is a great piece of the <b>welding tools</b> since it provides welder with a stable place to work and also help with both measuring and squaring.

They typically range in size from 6.5″ x 13″ to 20″ x 40″. Also, great for beginners since they aren’t expensive. So, you can find a welding fixture table for $20. No matter what size welding tables are, all of them are made from steel that is capable of withstanding the high and intense heat that comes with welding.

You can do various tasks with a welding table. Many projects need a welder capable of doing gauging, measuring, and square corners. It is the ideal platform for performing all of that without stress or extra difficulties. You can also exploit a welding table for mounting purposes, such as jigs and bending brakes.

A flat surface is required for precise welding, and a welding platform is the only one that can carry out that. Welding on the ground is unsuitable, comfortless, and dangerous, too. Before you begin a welding project, you need to find a solid surface to weld on. Either that’s a classic workbench or a standard welding table.

Even if you’re away and can’t work in your shop where is everything set up, there are a bunch of small and portable workbenches that can be bought for a nominal price. Put money into one of those and carry it with you, as it’ll make any work significantly easier.

Tool #8 Clamps

Everybody needs clamps, lots of them like C-clamps, pipe clamps, come-alongs clamps. Maybe you may have enough for the job, but you can never have too many.

It is a must-have piece of hand welding tools since it allows you to set up workpiece rmly so the welding will make a compact joint. Clamps come in various sizes. Therefore, it’s best to have at least 10 clamps, so you’ll always have one ready for the work.

Without metal clamps, the metal warpage produced by welding will bend application and cause welding defects.

It’s recommended that clamp projects to the table so that it’s completely xed and sti before the beginning of the welding process. Or the whole project will be warped, and it will be terrible and frustrating.

So, you should get some of these clamps.

- C-clamps are perfect for securing any workpiece. Therefore, having an assortment of C-clamps will save your day,

- Pipe clamps and bar clamps are used to clamp across long spans,

- Cable pullers, also called come-alongs clamps, are utilized to pull large, stiff or long parts into position. They are especially good on structural steel for pulling frames into a square,

- Bessey welding clamps are stronger and heavier than general-purpose welding clamps, also more expensive, but usually worth it.

Corner-clamping fixtures make getting right-angle joints easier. Even though these clamps are most often used sequentially to weld up corner joints, sometimes 4 or more are placed on a rigid base to form a fixture for the application. They have aluminum bases and copper-plated screws, so welding spatter does not stick to them. Their prices vary from $10 to $100 depending on clamp’s quality and durability.

Tool #9 Magnets

Not as secure like clamps, still very useful, the standard arrow-shaped magnets are good for 45°, 90°, and 135° angles. Magnets are also available in adjustable variants that pivot to hold at any angle. They are essential welding fabrication tool since they’re so versatile and inexpensive since they cost $10.

You can easily hold pieces in place and create 90-degree angles with any of projects. They’re great for building welding frames for tables, re pit grates, and more.

Magnets come in several dierent sizes for small welding projects all the way up to large projects. But make sure to purchase multiple magnets.

These tools are capable of holding tight work applications from dierent angles. These magnets will keep things in place. They’ll even enable the making of a 90-degree angle, which can sometimes be challenging.

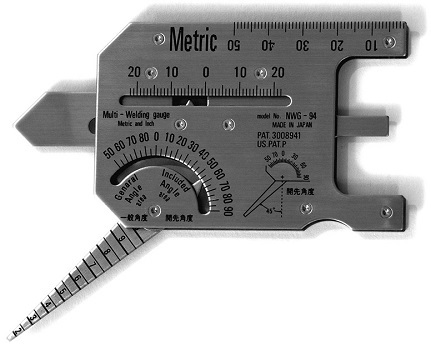

Tool #10 Measuring Tools

In the welding procedure, every measurement needs to be precise, and that demands using proper measuring tools. Referring to your project and preference, this usually means anything from squares, levels, compasses, measuring tapes, to soapstones.

You can purchase a whole set of measuring tools for $30.

- Squares – They’re great for checking joints and miters and marking pieces to be cut, while thicker models allow clamping directly to the work to maintain square joints while welding.

- Levels – It’s a measuring tool that along with a square help to keep projects accurate.

- Compasses and dividers – Ideal for scribing circles or stepping o a series of equal intervals.

- Measuring tape – It’s a handy accessory for measuring bent surfaces.

- Precision rules – Available in lengths from 6–72″, these rules are for measuring of welds.

- Soapstones – It’s applied as a marking tool when performing on metal. It’s useful since it withstands the high heat of cutting and welding torches. If you have shapes, you’d like to cut out with a torch, you would just draw the desired shape on the metal and then cut away.

Tool #11 Pliers As

Pliers As most of the tools we recommended so far, they are crucial because of their versatility. The welding pliers are drop forged steel constructed and come with a form-tting handle. They can be spring loaded for easy opening and closing or heat treated for durability, and all that for just $8.

If you need them to remove a hot nozzle, a contact tip, or clip wire, these cheap and ecient tools will save you plenty of frustrating moments.

MIG welding pliers are one of the most useful equipment if you maybe “dive” into MIG. Since they’re a multi-purpose plier, it’ll help to remove the nozzle from pipe welding tool. Therefore, it is a must have welding accessory for a MIG welder.

Once the project is completed, after so much welding and cutting you’ll notice a bunch of metal burrs and imperfections that will need to smooth out. You can use the angle grinder for bigger DIY applications, but for the small one, a metal fIle is a right tool.

You’ve probably used metal les before, if not on a welding project, then on an old vehicle to remove old paint. They’re great to use when nishing a project.

A metal le provides great work on smaller pieces and smoothes the welded details more precisely, and they are a very cheap solution, to begin with.

Also, it can be a useful investment, and they’re only $12.

Welding wire brushes allow thorough cleaning of the base material before welding and between each pass. To prevent contamination that will damage weld, it’s also signicant to have certain brushes for certain materials.

For example, brass for aluminum, stainless for stainless, and tempered steel for carbon steel. Buy an adequate set of brushes for $8 to boost weld quality and image.

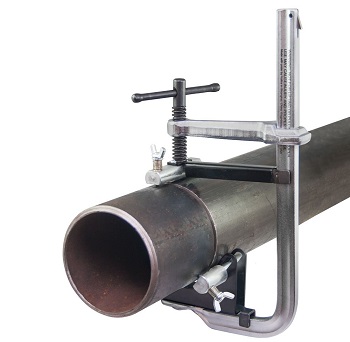

Tool #13 Pipe Welding Tools

Simply, pipeline welding tools in are perfect tools that minimized welding failures. Welders who work on pipelines often have to travel and have a higher risk. This is also a skill that is in very high demand and not a lot of welders tackle it. Because of this, pipeline welders make an even higher salary.

In the pipe welding process helpful tools such as pipe cold cutting machines, pipe welding stands, pipe beveling machines, pipe alignment clamps, pipe chain alignment clamps, and pipe jacks, provide improved productivity for welded pipe and a more suitable and safer working environment.

It’s costly equipment, and you will need a lot of bucks for these kinds of DIY projects

Welding consumables that provide matching or overmatching properties are required, depending on the applicable code or end-user specication.

Powerful welding equipment that can withstand the high demands of pipeline welding is often utilized. It’s essential that these requirements be a perfect mix of solutions, products, and support that can accomplish maximum productivity at minimum risk.

Tool #14 Welding Kit

Portable welding kits are great for away torch welding jobs- especially for metal repair work, welding tubes and pipes, or even artwork sculpture. Welding kit combines all the tools which allow the welder to be operationally ecient.

Terrible welding failures can occur when you’re working in remote locations. An onboard welding kit is cheap insurance to get you back on the trail towards home.

If you’re a new guy in welding, choose a small welding kit that cost about $30 to start with.

They are essential for mobile service professionals to conduct metal cutting, forming, bending, steel welding as well as brazing and braze-welding.

Welding kit can include tools from electrode holder, MIG pliers, assembled cable, shield with green glass, to soapstone.