10 Minute Guide to Know Everything About Brazing Steel

Brazing is favored joining technology by most custom frame builders working with steel. It’s a process for joining steel, copper, brass, aluminum, or any two metals with a filler material that melts, flows, and wets the metals’ surfaces at a temperature that’s lower than metals’ melting temperature. Steel melts at a high temperature and therefore are mostly used in furnace brazing under protective atmosphere. With adequate flux provided in the joint, brazing-steel can be done with mechanized torch setup or within induction coils, depending on requirements and available equipment. Protection from the oxidation of the filler metal and metal surface during the joining action is performed with a flux material or covering gas. Steel is utilized for countless applications in the joining of various metals including brazing copper to steel, brazing brass to steel, brazing steel to steel, and brazing steel to aluminum.Brazing Stainless Steel

The great majority stainless-steel types, except niobium or titanium, can be brazed. The 3 basic methods in common use for stainless steel brazing are:- Brazing in air with flux;

- Brazing under reducing atmosphere;

- Vacuum brazing;

Brazing in Air with Flux

In this kind of brazing, low-temperature silver brazing alloys are typically utilized. The fluxes used are often mixtures of alkali metal salts, which are solid at room temp. Fluxes need to be melted before they can start to dissolve the oxide film on the stainless surface. The flux must stay fluid, even when heavily laden with dissolved oxides, for it to be 'cleaned out' of the capillary gap by the advancing front of molten brazing alloy. The flux must be capable of wetting and staying on, vertical surfaces and the residue should able for efficient removing from the joint at the end of the brazing process. Generally, flux is best applied to the joints as a paste. Flux paste must be uniformly applied to the mating surfaces of the joint and the area right next to it.

These are crucial things to consider in air brazing with a flux :

- Quantity of flux used on the joint needs to be proper;

- Brazing process needs to be as short as possible;

- Brazing temp needs to be as low as possible;

- Heating must be balanced so that no part of the joint gets an excessive temp.

Brazing under reducing atmospheres

In this type of brazing, chemical reduction of the surface oxides provides the oxide-free surface that allows flow and wetting through the molten filler material. Therefore, this kind of brazing is generally performed in a continuous conveyor furnace that is coated throughout with heat-resisting alloys so the atmosphere can be retained.

Careful control of oxygen, hydrogen, and water vapor levels is crucial in furnaces employed for reducing atmosphere brazing.

Standardly, copper or copper-base alloys are used as the filler material in reducing atmosphere furnace brazing. It means that brazing temps are typically above 1935° F.

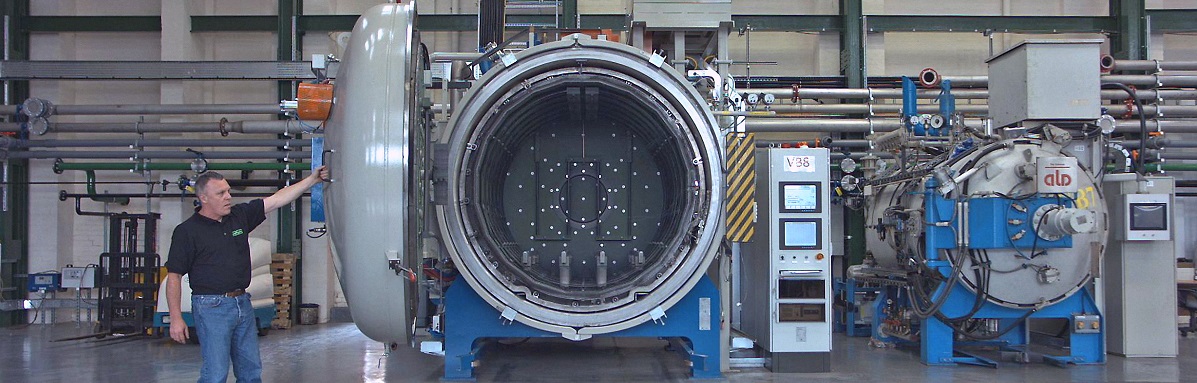

Vacuum brazing

In most applications where stainless steels are to be brazed in a vacuum, the high-temperature brazing rods for steel are used. Vacuum brazing temperatures are typically higher than 1830° F. It provides an opportunity to do some heat treatments as part of the brazing process.

As part of the process, the furnace can be “refilled” with an inert gas to help in “cleaning out” any residual air from the capillary trails of the surface to be brazed. This gas is removed before the brazing process starts. Inert gas can be applied to speed up cooling after the filler has solidified.

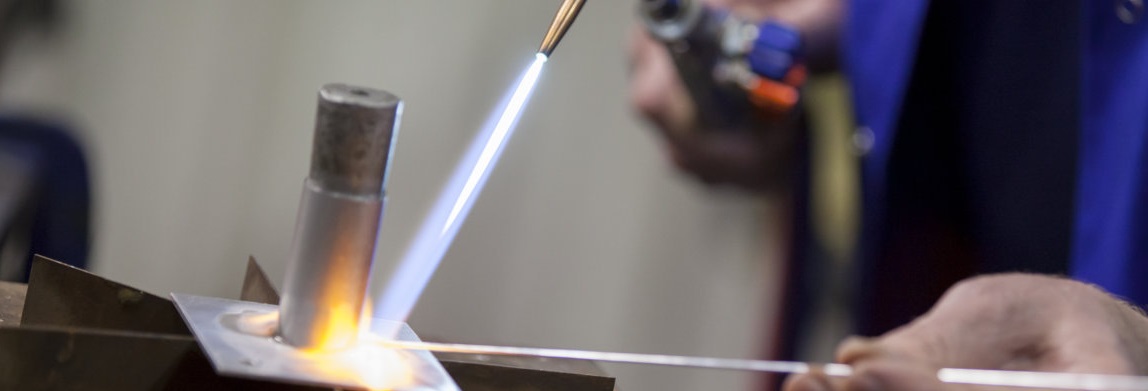

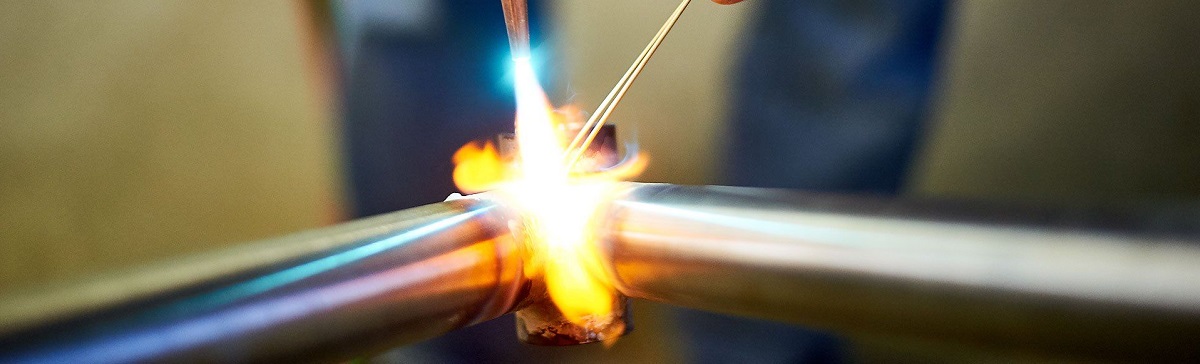

How to Braze Steel

Brazing is a method of joining metal pieces together by filling the join between the two metal pieces with molten metal. Brazing steel is generally easy to accomplish with the proper consumables and operations. Follow these steps and learn how to braze steel easily.- Wipe the surfaces on the parts that will be joined with the emery cloth, so the surfaces are free from grease and dust. In case the surface is quite dirt and rusty, use rotary tool with grinding wheels and eliminate rust and other surface residues immediately;

- Combine a small amount of flux with water to make a paste. Use a brush and apply the paste on the parts that will be joined;

- Put two parts on the rotating table and make sure they’re in the proper position;

- Activate the torch and apply the flame to the metal pieces for a short period, so that the water in the flux evaporates while the metals are hot;

- Apply the flame so that the tip of the flame nearly contacts the metal. Move the flame back over the surface to be joined until it becomes red;

- Hold the brazing rod for the steel versus the area to be joined. The rod should melt, and the brazing metal should flow into the gap between the two metals;

- Let the joint to cool slowly.

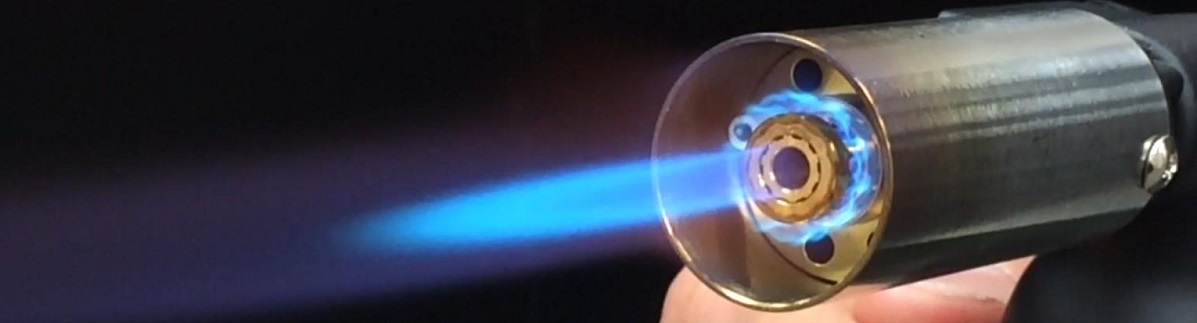

Brazing Steel with Propane Torch

Brazing permanently joins two metals with propane torch. A propane torch is usually used for brazing steel. Propane torches are available in hardware stores, plumbing supply houses, jewelry, and metalsmith supply companies.

Brazing steel with a propane torch can be pretty easy by following these instructions.

- Clean the metal you want to braze. Apply sandpaper to remove oxidation. Take acetone to remove grease. Use water and soap to remove dirt. Then, rinse with water and dry the clean metal;

- Put the metal on a fire-safe work surface. Arrange the metal you need to braze so that it can’t move. You can use a vise to hold the two metals if gravity doesn't hold the assembly in place;

- Heat the two metals you need to join. When the metals achieve the brazing temperature, use the brazing wire on the seam. Heat the brazing wire as far as it melts into the seam;

- Allow the metals to cool.

Brazing Steel to Steel

Practically, very little brazing is needed for the production of steel to steel connection. But you have to understand the process and all its fundamentals properly so that it can be applied to braze with a silver-containing filler metal. Only then the process can be reliable and cost-effective. Silver brazing is the most commonly utilized process for steel to steel joints. It uses a silver-containing alloy. Its melting point is above 840°F, but it must be below the melting point of the metals to be joined, like in brazing steel to steel.

The brazing operation comprises of base metals that are heated up to the point that is slightly above the flow point or liquid of the filler metal. Only then it melts, since the filler metal flows down into the parallel joint clearance.

This clearance is between the two base materials. And through capillary attraction, it bonds to the surfaces, while diffusion occurs to strengthen and complete the joint.

Brazing Aluminum to Steel

Joining aluminum to steel is done on a large scale commercially for the production of pans and pots, mostly in induction brazing. It's also used for the fabrication of heating elements such as tubes for electrical heating wires and steel heating plates with aluminum base plates. Brazing aluminum to a steel works both with flux and filler metal. Therefore, when the flux melts and the oxides are removed, there is a reaction between aluminum and steel, forming a thin intermetallic layer.

This layer forms the metallurgical between the steel and aluminum components. This combination of metals is very fragile, and so the thickness of the layer must be minimized, or the joint can easily crack.

From a metallurgic point of view, it is a multi-layer system. First, there is the steel layer, then the thickness of steel-aluminum, then the aluminum plus filler metal layer, and finally the aluminum base material.

The thickness of the brittle aluminum/steel layer is a function of brazing time and temperature. Therefore, the need for a short brazing cycle with fast heat-up and quick holding time at maximum temperature is imperative.

Too high brazing temperatures must be avoided. Since, only with a short brazing cycle, a successful joining of aluminum to steel is feasible.

Brazing Brass to Steel

The brass brazing is mostly oriented on capillary action which is the flow of liquid via a narrow space or a tube and versus the forces of gravity. When brazing brass to brass, there are 3 metals which are involved. Two of these are the base metals, while the third is filler metal which is utilized to join the parts.

Brazing is a favorite method of joining metals such as brass, because of the following benefits;

- The brass is easy to work, and it's economical since its compatibility with other metals and alloys. For instance, brazing brass to steel can be done with little or no difficulty even though the materials have different masses and components.

- The joints which come from brazing brass are great conductors of heat, they’re smooth, and are best suited for gas and liquid leakages.

- Due to the high melting point of brass metals, they aren’t affected with heating, only the filler metals are damaged in this action.